During the COVID-19 outbreak, my family and I decided to participate in one of the truest Canadian pastimes (at least in this side of the country): maple syrup production. In previous years, we joined in with my siblings at our family farm north of Kingston, ON and made about 75L of maple syrup (from about 100 taps – taps are holes in the trees to collect sap, trees frequently have between 2-4 taps).

With everything going on this year we stayed around our place and scaled things down quite a bit. We tapped 8 trees with about 20 taps. We ended up getting about 22L of syrup from 3 different batches (3 successive weekends we boiled all the sap we had collected for the week.

This year’s maple syrup season has come and gone, it’s roughly a 1-month (totally weather dependent) season. Sap (sweet water that comes out of trees, boiled down to make syrup) begins to run when temperatures rise above freezing during the day and dip back below freezing at night. Sap doesn’t keep indefinitely, it needs to be boiled or discarded within a week or two after collecting or it spoils). It’s a very time consuming task. Collection is done at least daily and boiling takes hours. Roughly, we collected about 850L of sap to make that 22L of syrup.

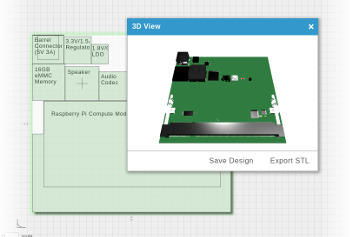

Of course being an engineer, I always try to come up with fun ways to geek things out. Combined with the extensive toolset provided by Geppetto, some cool stuff is bound to be made.

Last year I made use of our ESP32 devices with a temperature sensor and the Blynk/Cayenne apps to monitor and display (RGB matrix) boiling temperatures. I did use that setup again (minus the RGB) for boiling to know exactly when the syrup is ready (water boils at 100 degrees C, finished maple syrup is 104.2 degrees C, giving 67 Brix). This year I leveraged our Lora tech to enable remote monitoring of the sap collection.

Modern syrup producers have long since done away with spiles and buckets, most use a gravity suction setup using lots of small hoses. Hobby setups often use smaller buckets because it’s easier. They are still readily available at many hardware stores (at least around here) but have replaced the original metal buckets and spiles with plastic.

As you can see, we mostly used individual buckets with the exception of the home depot buckets that use multiple taps into a single bucket.

One challenge with this collection method is making sure you collect often enough so that the buckets don’t overflow. This was easy on the buckets outside our house which we could see but some buckets (home depot) were over a block away. I made use of Lora technology (low bandwidth, low power) to report the level of sap in the buckets.

Because of COVID restrictions, I had to improvise a few systems. This setup was thrown together in an hour and it’s actually the opposite you should be doing. Evaporator setups should be large shallow pans (to increase surface area for heat transfer and evaporation). Big turkey cooker pots are not how you’re supposed to do it, but in this case they worked just fine.

I had two remote sensors, one was powered off a solar panel that had an internal battery that output 5V. The other setup made use of a 3.7V 1200mAh Li-Ion battery.

Making use of the low power functions of the ARM M0 processor, the solar powered sensor operated indefinitely, reporting weather data and sap level every minute. The battery powered unit operated for two weeks on a single charge, reporting every 15 minutes.

Unfortunately, because of the delays in China the designs I intended on using were not ready in time so I made use of our existing RPi Lora gateway and Sparkfun boards. It’s interesting to note how much smaller the Geppetto design was than the Sparkfun boards.

The tech probably isn’t something a commercial setup would use but I thought it was fun. Next year I’ll have to think of another way of abusing technology, maybe an AI-controlled evaporator setup

RSS

RSS